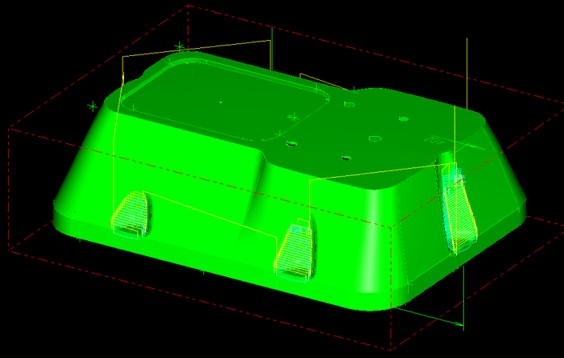

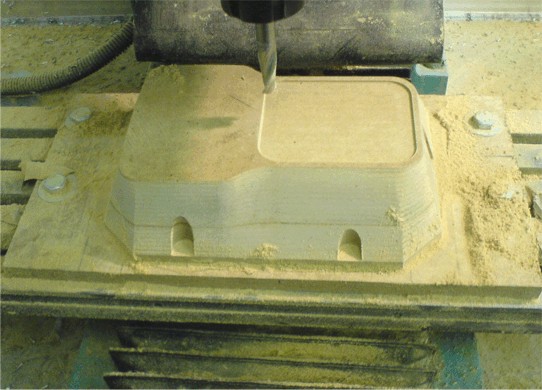

These images show the process of a recent project to create a complex tool for vacuum forming.

Beginning with CAD, the tool is created in 3D virtual reality and refined before moving to the prototype stage.

At the prototype stage a secondary material, in this case MDF, is used to create a 'dry run'. Once the prototype is approved, we create the final tool.

The final image shows the actual tool being machined in aluminium, ready for use within a vacuum forming machine.

Please contact us to discover more about the precision engineering services that we offer and how we can help you with your next project.

Horton Engineering

Tool Making & Mechanical Engineering Consultancy

11 Baskerville House

Barbourne Road

Worcester

Worcestershire

WR1 1RU

01905 863297

07884 003564

Tool Making & Mechanical Engineering Consultancy

11 Baskerville House

Barbourne Road

Worcester

Worcestershire

WR1 1RU

01905 863297

07884 003564